Cable Harness Design - Hand Laid Cables v Manufactured Cables

Posted on 30th January 2023 at 14:17

Military systems are some of the most advanced and complex systems in the world. They require high-quality cables to function properly, and that's where Cablescan is committed to offer a solution. Hand laid multicore cables can offer two distinct advantages over a machine manufactured cable.

What is best 1000m or 5m?

Quantity - if the overall multicore cable requirement falls short of the manufacturer's MOQ, we're able to hand build a vast majority of constructions. This reduces the amortisation of the cable cost. For prototype assemblies, the use of hand built multicore cables as part of the overall cable assembly allows for testing and approvals to be undertaken using only the quantity needed. This will potentially save expenditure on purchasing a larger quantity, only to find the design needs changing.

Do you want to wait 26 weeks or 2 weeks?

Lead Time - if the cable components are available then we can usually start manufacturing within weeks. So, in conjunction with using a smaller quantity of cable, the deliverables are certainly in your favour. The reality being the time from design approval to delivering the cable could be critical within your overall project plan. Cablescan understand these critical milestones and our commitment to manufacturing hand built multicore cables is testament to our support on development projects for Military projects.

Design Criteria

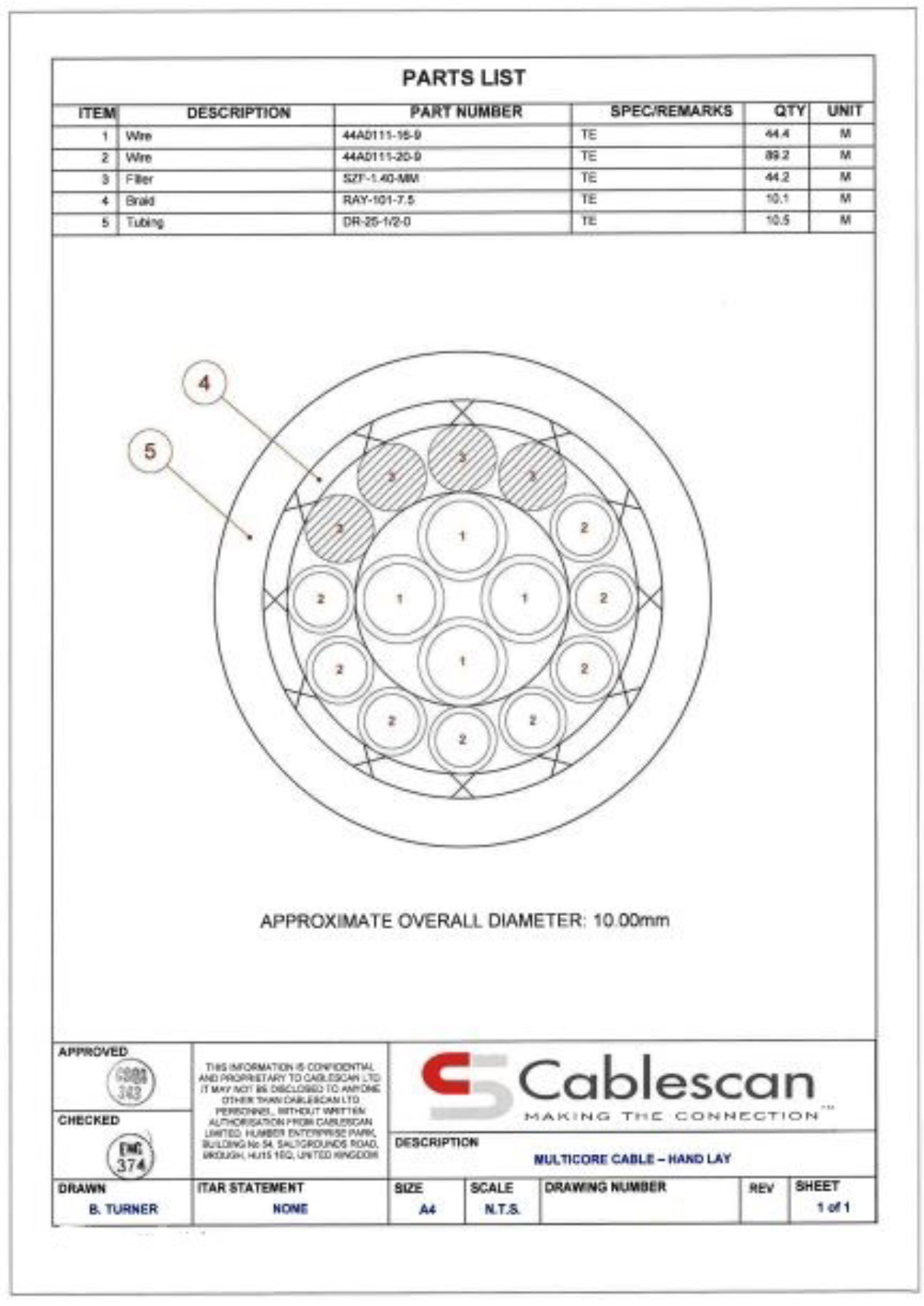

The integrity of the cable design is maintained by utilising our design software to produce a detailed drawing for our customer to approve. The design ensures the concentricity of the cable, allowing maximum flexibility. The drawing will show the cable construction including the parts used.

The application of the cable dictates the type of components that are specified. For Naval applications we focus on using low smoke, zero halogen conductors. The outer jacket will also be low smoke zero halogen. For military vehicles the design will focus on diesel and abrasion resistant outer jackets.

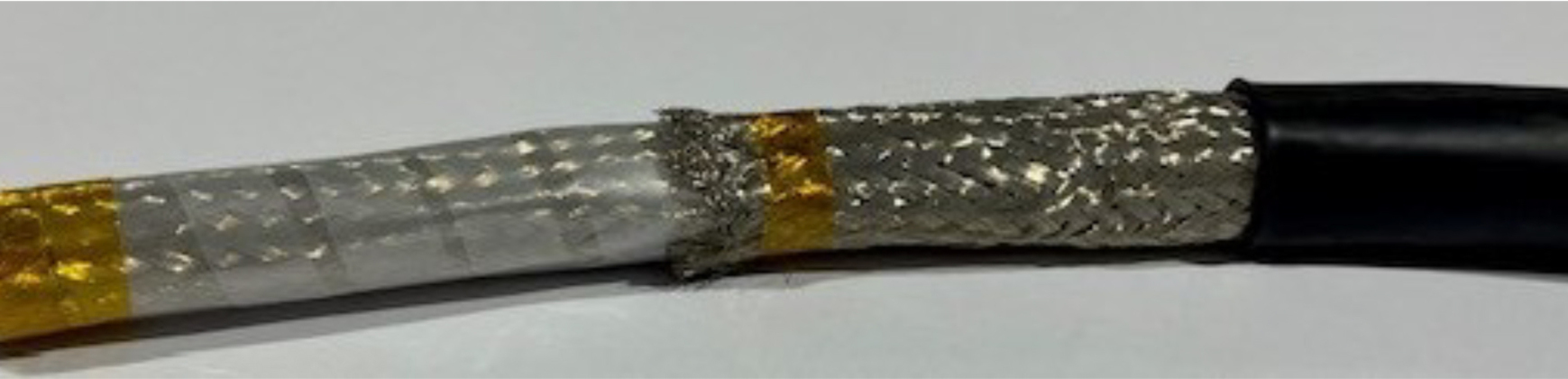

As shown below, lacing tape is used to bind the conductors together. A mylar wrap is used under each screen if multiple screens are required.

To find out more about how Cablescan can help with your next project, call us on +44 (0)1482 873073 or email [email protected]

Share this post: